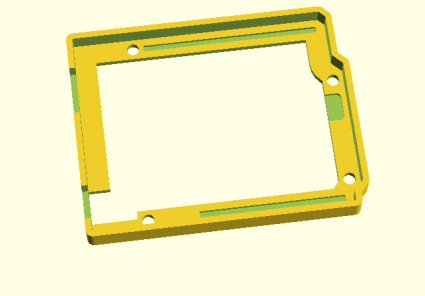

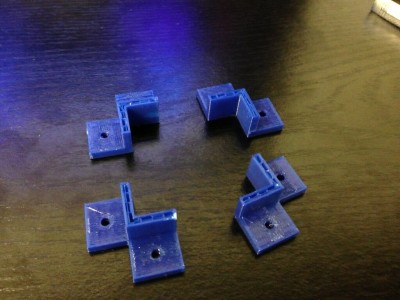

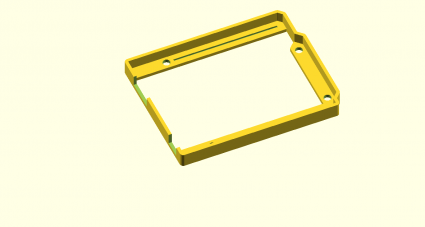

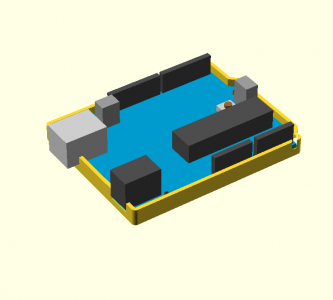

Okay, our Replicator 2 went back online this week, and I decided to give printing my Arduino bumper another try. Since the last time, I have revised the program and code a couple of times. I was concerned that the various bits of solder protruding from the bottom of the board would need extra relief cuts. As I tried to account for more and more of these, I decided I did not like the design especially well, so I took a different tactic: I decided to make the bumper’s walls as thin as possible, and only include an area around each of the Arduino bolt holes. This minimized the amount of material needed, and also means that it could be printed more quickly.

And so, I printed it out. I use the Makerbot software, set for the Replicator 2, once using medium quality (with a print time of about sixteen minutes) and once using the high quality (print time of nearly an hour). I used 25% infill for both, I wanted to make sure the outer and inner shells were sufficiently bonded. I then printed it!

Printing my Arduino bumper… vine.co/v/bDMwPEOzFZ6

— Mark VandeWettering (@brainwagon) March 22, 2013

No real failures in this round of 3d printing, but the chicken needs some sanding to fit together… twitter.com/brainwagon/sta…

— Mark VandeWettering (@brainwagon) March 23, 2013

But there were a few issues.

First of all, my Arduino bumpers were a pretty tight fit.

My bumper fits, but it is tight.Increase clearance to .012” and more clearance for connectors… twitter.com/brainwagon/sta…

— Mark VandeWettering (@brainwagon) March 23, 2013

I coded in a clearance of 0.008″ around the nominal board size, but that was simply not enough. I think I’ll expand that to 0.012″ or even 0.015″ next time around. I was able to press fit one of my OSEPP Arduino boards into it, but just barely, and only by shaving a small amount off one corner of the board with an Exacto knife. I also think I should thicken the bottom slightly: if you used this shield to bolt against a conductive surface, some of the solder joints on the bottom of the board could still short out. I am also thinking of widening the channels cut for the USB and DC jack a small amount, they fit, but just barely. An additional 0.02″ of an inch would make them more comfortable. I also noticed that one of the prints had a corner which seemed to pull up and not be level/coplanar with the rest of the print. Not sure what that was about. But overall it worked! I’ll make these changes to the design, and then try another set of prints, and then you should be able to see it on Thingiverse.

Extra space will help clearance for the #4 screw heads too.But it works as a spacer with my @tautic breadboard. twitter.com/brainwagon/sta…

— Mark VandeWettering (@brainwagon) March 23, 2013

I also printed this model of the chicken from Minecraft. It comes in four parts (body, head, two feet) which you can assemble and paint. The model is quite simple, I printed it with medium quality settings and 10% infill. It worked rather well, except that the parts do not assemble easily: the head is slightly too wide to fit into the slot in the body and the feet do not fit into the holes left in the bottom. I think a little judicious belt sanding will make the head fit, and I’ll measure and redrill out the holes to make the legs fit. But in general, the issue of clearances seems to be one I need to explore more. Does anyone have any good references/hints/guides they would like to share?