Brief experience (failure) printing with Sainsmart TPU

I’m still heading toward changing my Creality CR-10 over to use a BLTouch bed leveling sensor, but I still need a few parts that I’m waiting on. I thought it might be a good time to try some prints with a filament that I never used before: namely a roll of Sainsmart TPU filament that I bought months ago but was too chicken to try.

TPU is a soft and stretchy filament which presents some challenges, especially for prints like the CR-10 which uses a Bowden extruder. The filament is pretty soft and compressible, which means that the extruder has to work very slowly to keep the pressure down sufficiently to keep it from bunching up and jamming in the printer. Most people also recommend modifications to the extruder to make sure that the filament enters the feed time immediately after exiting the feed gear. Otherwise a common failure mode is for the pressure to build up and for the filament to kink right there, causing extrusion to stop. My new aluminum replacement extruder hardware seemed pretty good from this perspective, so I thought I’d give it a shot.

I used most of the suggested settings from the Sainsmart page, which basically meant slowing down the print speed to between 15mm and 30mm/s, and go even slower on the first layer and to disable retraction. For my first test print, I decided to use a calibration cat that I often use for test prints, and is slightly less boring and not much more difficult than a simple cube.

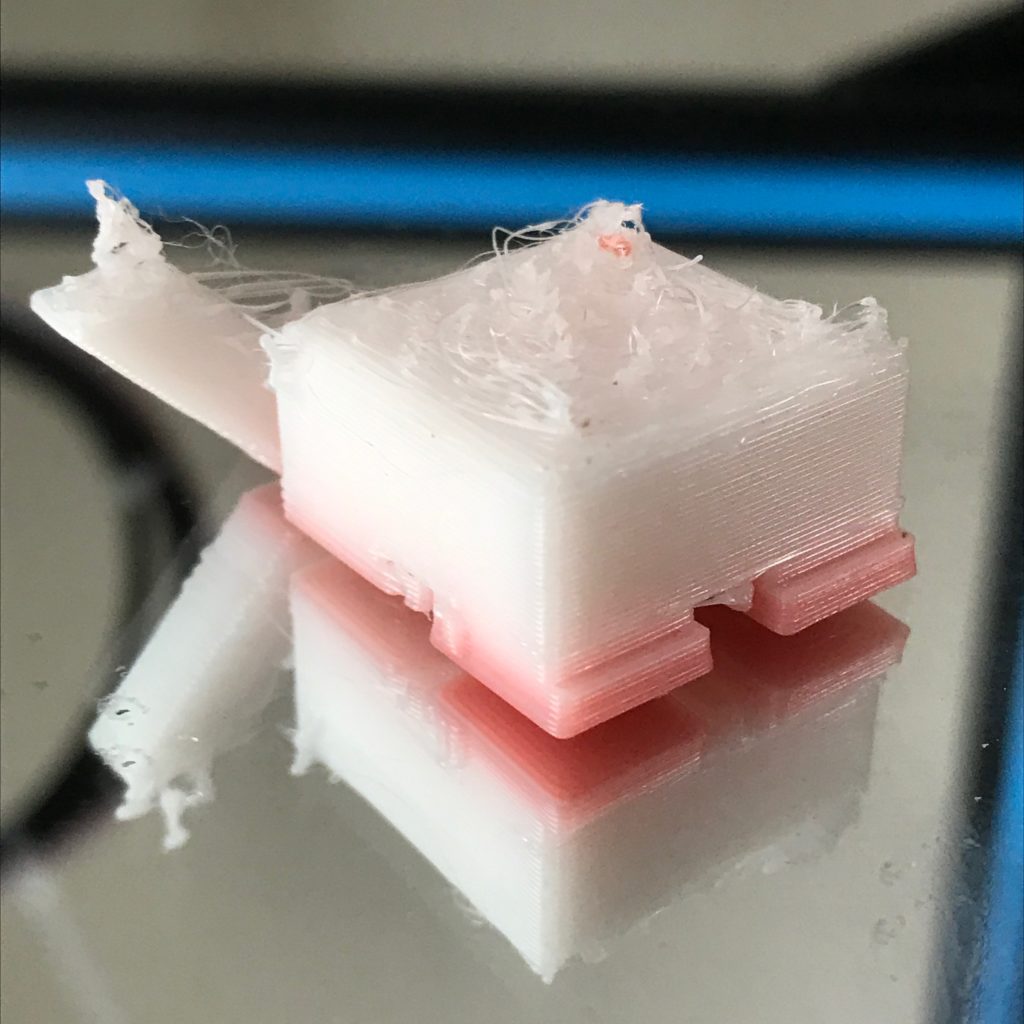

Sadly, it didn’t go particularly well. I had two failures in a row which were basically caused not such much by filament backing up in the tube, but by some back pressure causing the drive gear to stop getting traction on filament, and it just ceases to advance. This happened about 1cm into my first print, so I decided to up the temperature a bit to hopefully reduce the pressure and try again. That print failed almost immediately, about three layers in.

This caused me to abort my attempt for the day, and go off and scratch my head some more.

The obvious things to try would seem to be:

- Additional temperature changes (higher, perhaps as high as 230?) but I think that higher temperatures also increase stringing and other undesirable problems.

- Make sure that my drive gears are sharp and see if I can increase the tension on the drive spring.

- Go even slower. Perhaps 15mm/s or even 10mm/s is reasonable.

Anybody have any other suggestions?

I recall burning three or four weeks of a sabbatical getting Saccade.com on the air with Wordpress. So much tweaking…