Day 11, My kerfmaker

A lot of woodworking is about making jigs. This one is perhaps one of the smallest, but also one of the most useful, a kerfmaker.

To understand what this does, imagine you want to make a bookshelf using some 3/4" lumber. Rather than just using a simple butt joint to attach the shelves, you'd like to cut a precise slot into each side, so that instead of relying only on the glue joint and/or screws, the shelf will sit inside a snug fitting slot. That way, even if the glue joint or screws fail, you will still have a mechanical support of the side wood to hold the shelf up.

So, the question is, how do you cut this slot? There are of course all sorts of ways to do so, but let's say you want to cut the slot using your table saw. There are special blades (so-called dado stacks) which you can use that will plough out the slot in a single pass. But they have a number of disadvantages. You need to change the blade of your table saw, and when you go back to making regular cuts, you'll need to change it back. Or perhaps your table saw doesn't even support these kinds of blade. Mine (a small DeWalt) doesn't have a sufficiently long arbor to hold these kind of thick stacks. Other saws may have insufficient power to cut harder materials with these wider blades. And, of course, these blades cost more money.

So, a common technique is to cut them with a regular (although probably flat toothed) blade. You might think, "Okay, I want to cut a (say) 3/4 slot." I'll set the fence on my table saw to cut one side of the slot, then move it over 3/4", and cut the other side. That should work perfectly!" I know I thought that would work when I was a beginner, and learned immediately what everyone knows. That doesn't account for the thickness of the sawblade, also known as the kerf. When you shift the blade over to cut the other side, you need to subtract the width of the blade.

But what is the width of your blade? Do you want to do that math every time you cut a dado? Do you trust the measurement of your fence? Can systematic errors creep in?

And of course that 3/4" plywood you have is almost certainly not 3/4". It might be 23/32". Did you take that into account?

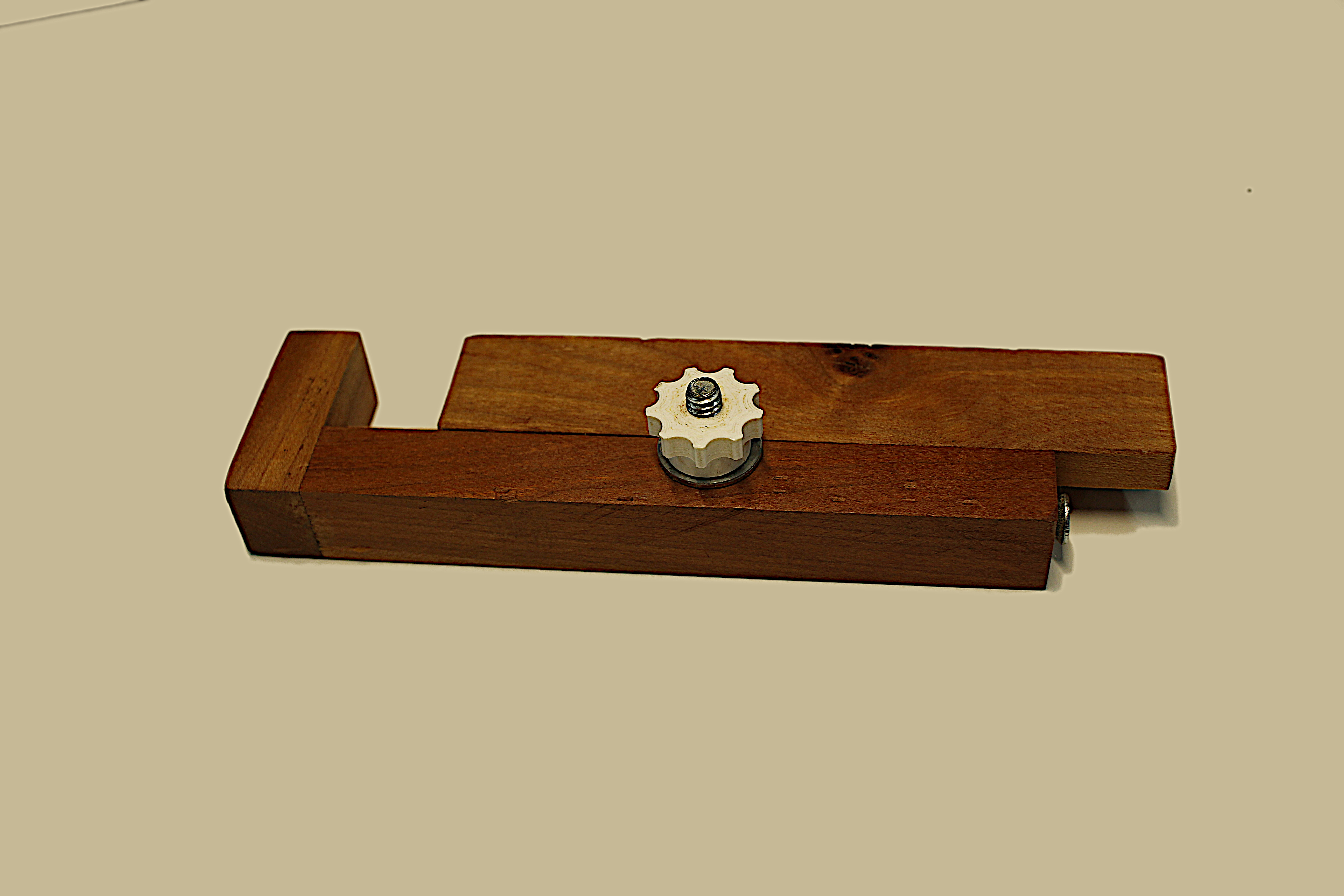

This is the problem that a kerfmaker is designed to solve. It basically looks like a small adjustable wrench. You loosen the white thumbscrew on one side, and slip the board that you want to use as a shelf into the mouth at the left. You can then tighten the thumbscrew, locking the slide into place.

Now, the kerfmaker serves as a double spacer block. Across the top, the distance is some distance (it actually doesn't matter what it is). The gap along the bottom caused by the offset is the the same as the thickness of the board. But if you look closely, you can see the head of a screw. This is the way that you adjust for the thickness of the board. You tighten or loosen the head of the screw until it is the thickness of your saw blade. When you use this side as a spacer, the screw accounts for the thickness of the blade, and you can cut the opposite side of the dado. You can then nibble the material in between those two cuts, and voila! A dado!

If that was not clear (it probably was not) you can dig around on YouTube and find a better explanation and demonstration. Here's one.

Mine was made out of a small scrap of cherry, a bolt that I had lying around, and a 3D printed nut to serve as the thumbscrew. It works perfectly, but is a touch unrefined. I could probably do better if I made a new one, but I have not felt the strong need to spend the thirty minutes or so to make it better. I believe that I made this one after watching his great video from the Pask Makes channel on YouTube.

You can also buy one from someplace like Aliexpress for $25 or so. The commercially manufactured ones often allow you to adjust to the width of different bits more quickly. This means that you could probably use it with a router table. Might be worthwhile getting one in that case.

That being said, I am glad I made one. It is simple, useful, and teaches you something about how to make reproduceable cuts using jigs while simultaneously not having to measure or do math.

A total win. After all, who wants to do math on Friday?

Hope you all are well.