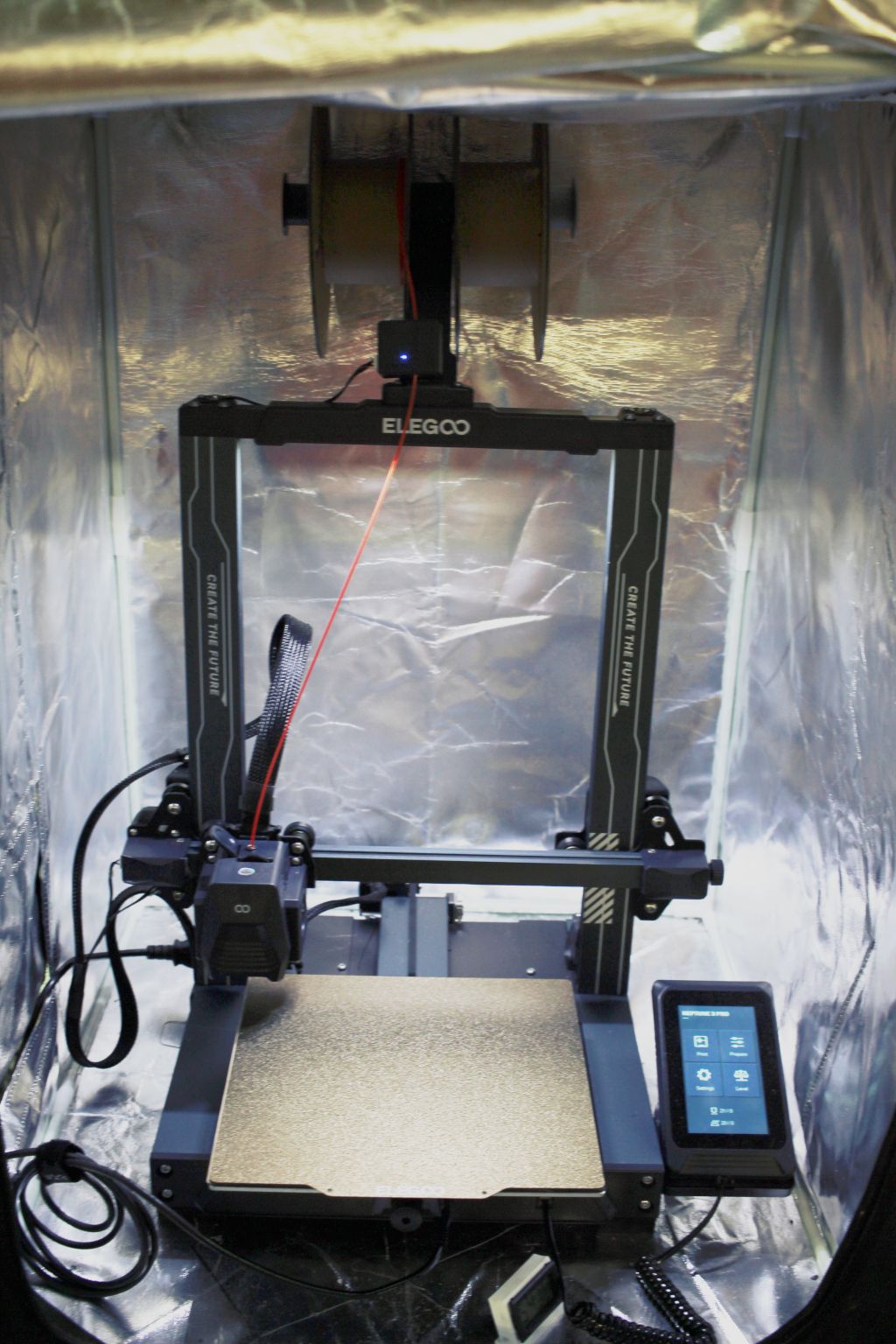

Day 40, My Elegoo Neptune 3 Pro

Anyone who has been following me for very long knows that I've been interested in 3D printing for quite some time. I'm currently on my third generation of 3D printers, having begun with an ANET A8 which was really more of a science fair project, progressed to a Creality CR-10 which I eventually modified to the point that it was screwed up beyond my ability to fix (or at least beyond my patience level to fix.)

So last year rather than spending time and mental energy on fixing that printer, I got an Elegoo Neptune Pro 3 during a black Friday sale for about $230. Unlike the ANET and Creality machines that I had before, this machine has largely been unmodified since I got it, simply because I haven't felt that it needed to be modified. It has churned out print after print with over a 95% success rate. There are without doubt better printers available now, but given all the use that I've had over the last year and a half makes it an obvious no-brainer.

It has a number of good features, especially compared to the previous generations that I was used to.

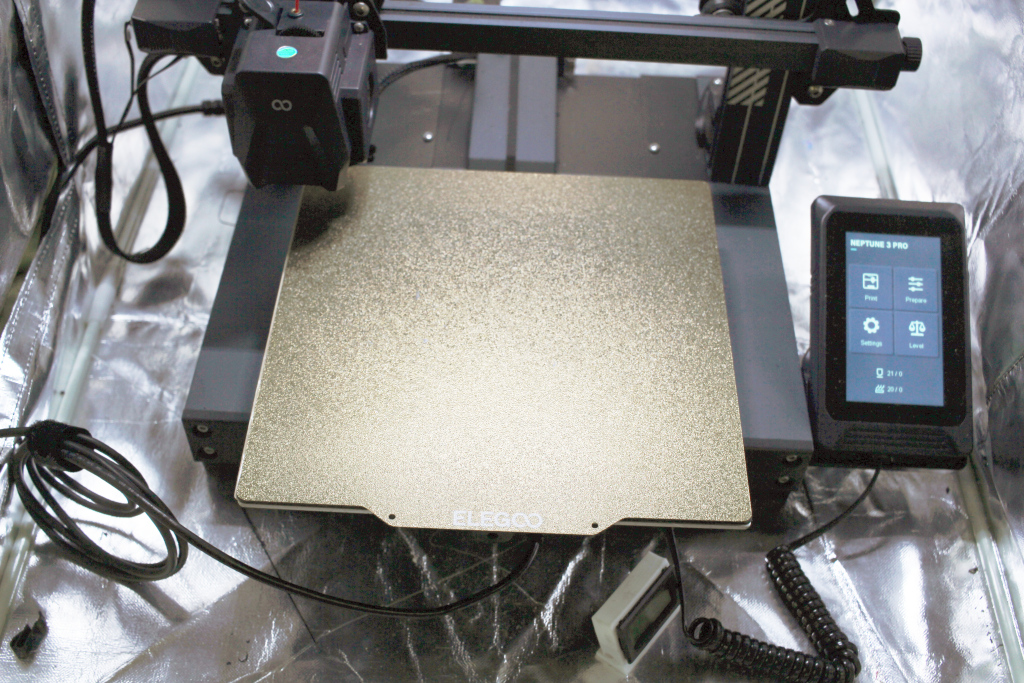

- It's reliable. The only time I had difficulty with it was when I damaged the build plate with acetone, and stuff began not to stick to it. I replaced that for $10, and it's worked very reliably since then. I chalk that up to my fault.

- It's got a decent sized build plate (235mmx235mm), which is big enough to handle most of what I'm interested in building (but see below).

- It includes automatic plate leveling, which is the #1 cause for failed prints. While not flawless, and I'm told that there are better implementations out there now, it works very well, and much better than trying to manually level the bed.

- It has a nice touch pad interface, but I almost exclusively drive it with OctoPrint, the print management system that runs on a Raspberry Pi that I have mounted to the side of the table. I have had some minor problems with it when the filament run-out sensor trips, but overall it's been great, and I spool all my prints from my desktop or laptop in the house.

To keep dust off it (since I do woodwork and the like in my garage) I purchased a Sunlu Printer Enclosure which is basically a tent frame lined with fireproof mylar. It's plenty large, and was inexpensive and one of the better quality of life improvements I made. My previous printers was stored in our dining room, which occasionally brought annoying glances from the misses, and it's simply better out in the garage.

That being said, I must say that I have a number of things that I wish my 3D printer had.

- I wish it was faster. At the time this printer was being created, significant improvements in firmware and hardware have made printers to be substantially faster. Mine operates at rates which are always under 100mm/sec, whereas modern "klipper" based firmware and the CoreXY designs often have velocities that are 500mm/sec or more. I have investigated "overclocking" this printer, but I am not willing to trade the reliable successes that I have or spend a ton of time to tweak things. I suspect that the extruder may actually be a limiting factor here, with an inability to heat enough filament to handle the higher flow requirements. My machine also lacks the ability to characterize vibrations which modern printers have. I've decided this kind of performance will be something that I seek in my next printer.

- I do wish it was bigger. 235mmx235mm is a good size, but I have been wanting to occasionally print bigger parts. The side panels for my LowRider CNC machine had to be split into two parts (did the glue up this evening). I have a couple of telescope projects which might be useful to have some additional space. I was looking at the Neptune 4 Max (which comes in at a reasonable $439) and it sports a 420x420mm build plate, which is awesome.

- The Neptune 4 Max also includes the Klipper improvements that make faster printing, as well as an upgraded hot end. My Neptune 3 is limited to about 240C, which means that some of the higher performance filaments are beyond its capabilities. The Neptune 4 Max can go up to 300C, which means that nylon filaments and other more exotic materials are within the realm of possibility.

- Many of the prints I do are more "functional" than artistic, and so are bigger and chunkier, which means it would be cool to have a larger nozzle to build more rugged parts at a greater speed.

For a while, it seemed like everyone in the Youtube-iverse was getting Bambu Labs printers, which indeed seem to have a side variety of capabilities, including the possibility of printing with multiple materials. While I occasionally think that would be cool, I don't see a huge need for that kind of functionality. The functionality the Bambu Labs H2D is impressing, and includes laser cutting and dual print heads, but this is a hobby for me: I doubt the $2K price tag is something that I'll be paying soon.

Something more in my hobby budget is the Elegoo Centauri Carbon a new printer by Elegoo. It only has a modestly larger build plate than my printer (256x256mm) but includes a ton of upgrades, like a full heated chamber, CoreXY speeds, built in air filter, and all sorts of other goodies. These have begun to show up in the hands of Youtubers, and initial impression seems quite positive. They also tease that multi-material printing may be coming. Oh, and the price? $300. Astonishing, and about what I paid for the Neptune 3 Pro and its associated tent.

3D printing is becoming something that I am using as part of my normal tinkering. And the future looks bright for future workshop projects.