Day 63, Balldrivers, (and a Kobalt router)

Today I thought I would try to spend a bit more time in the shop and make some progress on my Lowrider CNC router project. Between my break for my anniversary and general malaise, I haven't done much with the project. I think I really need to go out and get some MDF to serve as the table platform before I will make significant progress, and I haven't felt like doing that. Perhaps this weekend it will happen.

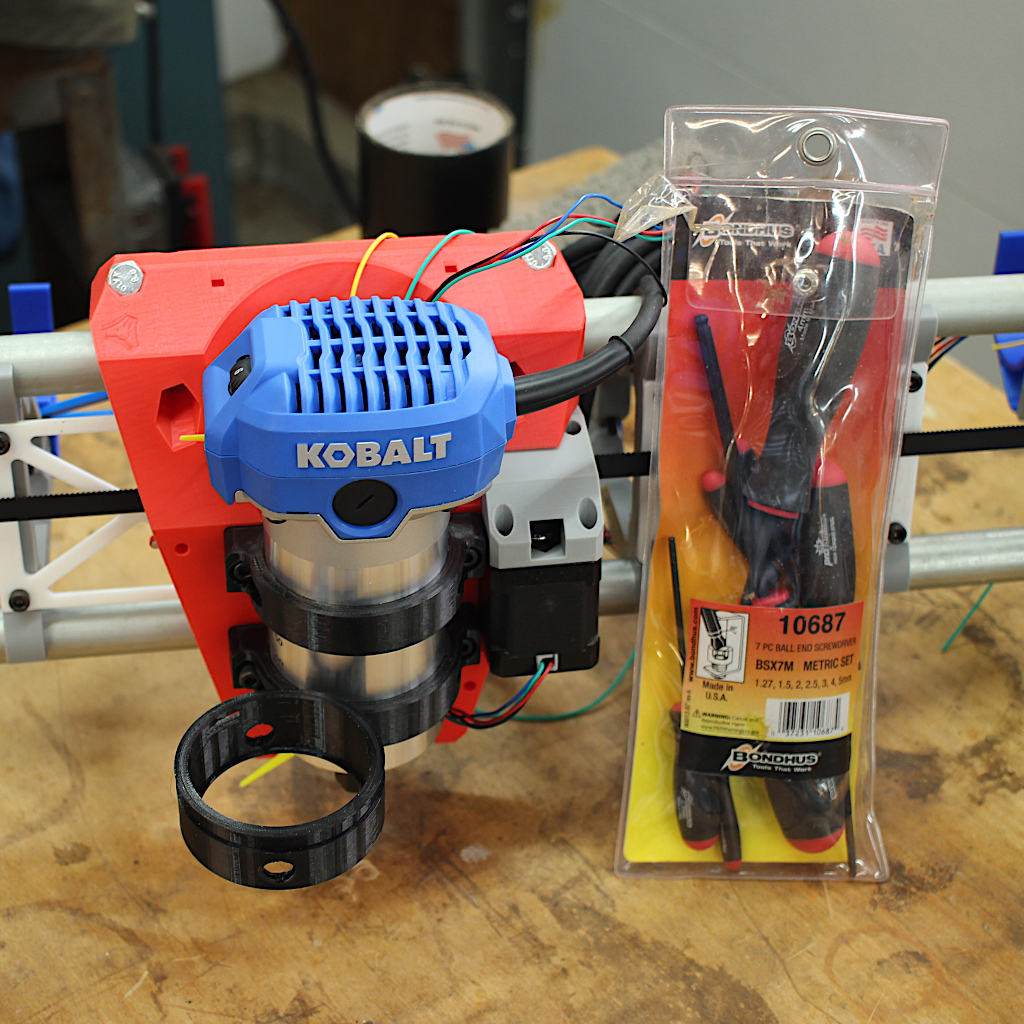

But there was one thing I wanted to do that I thought I had all the pieces for: mount the router on the gantry of the CNC. I had printed these parts over a year ago, and didn't even write down the url where I got them from, and honestly hadn't thought about how they went together. I dug the pieces out of the the bin where I had stored them, and stared at them. Then I went back and looked at some videos and pictures of how they were supposed to go together.

It began to make sense to me, so I thought I'd go ahead and test mount the router.

The Lowrider CNC can be adapted to a wide variety of trim routers, but I chose this Kobalt model from Lowes for a variety of reasons. First of all, I got in sale, and it was very cheap, only $60 on sale when I bought it (it lists for $99). Next, it was actually designed with some features that make it good for CNC use, like an ER11a collet and a low RPM range. I don't know whether they were especially successful, as now the router is out of stock on the Lowes webpage, and no hint as to when they will be restocked. It doesn't really much matter, as there are a wide variety of adapter rings for the Lowrider, and it wouldn't be hard to adapt any of the common models to fit.

Anyway, so I dusted off my collection of metric ball ended drivers and set to work.

What are "ball ended drivers" (or balldrivers)? They are basically hex wrenches (

aka Allen wrenches) but instead of having a straight hex profile at the end, they are rounded

into a ballshape, like below.

This means that you can use them a bit off axis, at angles up to about 20 degrees, which makes them more comfortable and faster to use. I also rather like to have these as "screwdriver" form factor, rather than the L shaped Allen keys, as they are simply more comfortable and fast to use.

Aside: I hate most Allen keys. Not only are they somewhat clumsy to use, but they are mass produced and often of terrible quality. Particularly in the smaller sizes, they have an annoying tendency to round off and become useless. I view the ones you get as part of many tool kits (or 3D printers) to be effectively disposable.

So, a while ago I spent $25 and acquired a set of Bondhus metric balldrivers, the 10687 set and have been generally very happy with them. The CNC project would have definitely given me Karpal tunnel syndrome if I had to drive all the bolts with just L shaped Allen wrenches. The quality of Bondus is generally very good, and orders of magnitude better than every cheaper alternative I've tried.

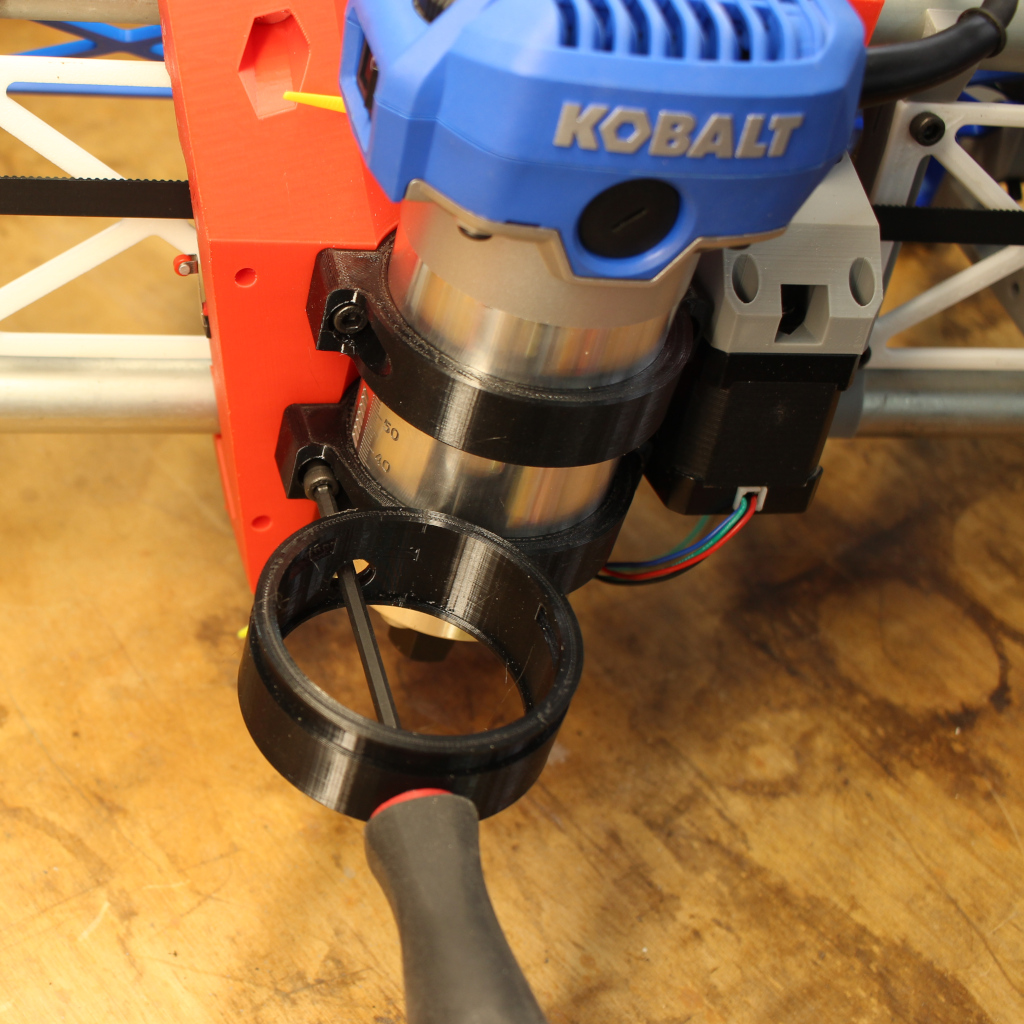

So, I set to work. There are two rings that bolt into the main "core" section, and thread into nylon lock nuts in the core. The rings both have a gap which allows it to grip the round body of the router, and a small slot that allows the stepper motor wires and the limit switch wires to pass up through the top. The top ring wasn't any problem. The bottom ring was unusual though. It has a separate ring section which is used to mount a vacuum hose so that you can do dust extraction. Because of the angle that it's mounted, it blocks access to the screw that you need to tighten. They thoughtfully provided an access hole so that you can reach it.

But... the standard Bondhus 4mm driver I have is too short to reach it through the body of the ring.

Sigh.

I can see a couple of ways to proceed at this point.

- Get a set of longer balldrivers. Bondus sells sets of long and extra long balldrivers on their website, as well as individual ones. I suspect that in most cases, I will have very little use for longer balldrivers, so it seems buying a complete set may not be the best use of money.

- Buy the one I need. The long 4mm one is model number 10760, and costs about $10. This is a size that I am more likely to use, so perhaps the investment is worthwhile.

- Buy a cheaper one. Even if they are crap, it will sastify my current need.

- 3D print a different design that doesn't have this "feature". I think it might be worthwhile doing anyway. I don't love the lower ring design on this one, and I have lots of PETG filament lying around.

I'll spend some time thinking about it anyway.

Hope you all are having a great Thursday!