So, my idea is to use a cheap but reasonably accurate RTC chip module based upon the DS3231 chip to periodically wake a sleeping Arduino. I tried getting it working yesterday, but had little luck. I don’t know whether it was Bailey’s insistence on being petted or simple sleep deprivation, but it eluded me yesterday. Today, I decided to go about it more methodically, and with the help of my trust Rigol DS1102E oscilloscope, I made sure that the module was generating a proper pulse stream, and eventually stumbled on the right order of operations to get this working.

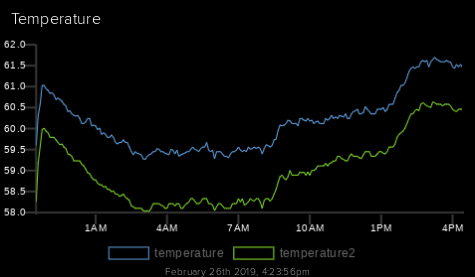

For the purposes of this demonstration, I’ve programmed ALARM_2 to trigger every minute (it fires when the seconds are 00) and then programmed ALARM_1 when the trigger matches 30. This means that the interrupt fires to wake up the Arduino every 30 seconds. When it wakes at the moment, it doesn’t do anything particularly interesting: it just prints the time and temperature (which doesn’t seem right, so I’ll have to dig into why).

Anyway, the code isn’t particularly complex, but there were a few details to work through, and it might be useful in the future. It will require a tiny bit of extra work to (say) trigger every 5 minutes. You basically will have to use the setAlarm function to set the alarm to go off at a particular point in the future, and when that alarm is triggered, then tell it to trigger again 5 minutes in the future. I don’t foresee any trouble.

Anyway, here is the code:

#include <LowPower.h>

#include <DS3232RTC.h> // https://github.com/JChristensen/DS3232RTC

#include <Streaming.h> // http://arduiniana.org/libraries/streaming/

#include <Wire.h>

/* _ _

* | |_(_)_ __ ___ _ _

* | _| | ' \/ -_) '_|

* \__|_|_|_|_\___|_|

*

* Some simple code to test the idea of using a DS3231 module's "alarm"

* functions to periodically wake up an Arduino which is in POWER_DOWN

* mode so that it will do something interesting. This is really just

* a skeleton now, but will serve as an outline for a more advanced sensor

* sketch.

*

* Written by mvandewettering@gmail.com

*/

const int wakeupPin = 2 ;

volatile int woken = 0 ;

void

wakeUp()

{

woken = 1 ;

}

void

setup()

{

pinMode(wakeupPin, INPUT_PULLUP) ;

pinMode(LED_BUILTIN, OUTPUT) ;

Serial.begin(115200) ;

delay(50) ;

Serial.println(F("WAKING UP...")) ;

Serial.println(F("I2C set to 400K")) ;

Wire.setClock(400000) ;

setSyncProvider(RTC.get); // the function to get the time from the RTC

if(timeStatus() != timeSet)

Serial.println("Unable to sync with the RTC");

else

Serial.println("RTC has set the system time");

Serial.print("::: INITIAL TIME ") ;

printDateTime(RTC.get()+7UL*3600UL) ;

Serial.println() ;

delay(50) ;

// initialize the alarms to known values,

// clear the alarm flags, clear the alarm interrupt flags

// ALARM_1 will trigger at 30 seconds into each minute

// ALARM_2 will trigger every minute, at 0 seconds.

RTC.setAlarm(ALM1_MATCH_SECONDS, 30, 0, 0, 0);

RTC.setAlarm(ALM2_EVERY_MINUTE, 0, 0, 0, 0);

// clear both alarm flags

RTC.alarm(ALARM_1); RTC.alarm(ALARM_2);

// We are going to output the alarm by going low onto the

// SQW output, which should be wired to wakeupPin

RTC.squareWave(SQWAVE_NONE);

// Both alarms should generate an interrupt

RTC.alarmInterrupt(ALARM_1, true);

RTC.alarmInterrupt(ALARM_2, true);

}

void

loop()

{

// The INT/SQW pin from the DS3231 is wired to the wakeup pin, and

// will go low when the alarm is triggered. We are going to trigger

// on the falling edge of that pulse.

attachInterrupt(digitalPinToInterrupt(wakeupPin), wakeUp, FALLING) ;

// Go into powerdown mode, waiting to be woken up by INT pin...

LowPower.powerDown(SLEEP_FOREVER, ADC_OFF, BOD_OFF) ;

// For now, let's just ignore transitions on this pin...

detachInterrupt(digitalPinToInterrupt(wakeupPin)) ;

// We have to clear the alarm condition to make the pin go back to

// the high state. I'm clearing both of them, because we are

// triggering every 30 seconds (in this example)

RTC.alarm(ALARM_1) ; RTC.alarm(ALARM_2) ;

// Now, we can do whatever we want to do. For now, we just get

// the current time and the temperature (which doesn't appear to

// work, and will be what I'm investigating next)

printDateTime(RTC.get()+7UL*3600UL) ;

Serial.print(" ") ;

Serial.println(RTC.temperature()) ;

delay(50) ; // allow serial to drain, otherwise we'll go to sleep

// before the buffer empties.

}

void

printDateTime(time_t t)

{

Serial << ((day(t)<10) ? "0" : "") << _DEC(day(t)) << ' ';

Serial << monthShortStr(month(t)) << ' ' << _DEC(year(t)) << ' ';

Serial << ((hour(t)<10) ? "0" : "") << _DEC(hour(t)) << ':';

Serial << ((minute(t)<10) ? "0" : "") << _DEC(minute(t)) << ':';

Serial << ((second(t)<10) ? "0" : "") << _DEC(second(t));

}

If it turns into something more interesting, you all will be the first to know.

Okay, it’s not really a “kit”, it’s just some directions on how you can wire some commonly available gadgets (like a Nokia 6100 LCD panel or a piezo speaker) to an Arduino board and make a nice little demonstration board. Some good ideas in here.

Okay, it’s not really a “kit”, it’s just some directions on how you can wire some commonly available gadgets (like a Nokia 6100 LCD panel or a piezo speaker) to an Arduino board and make a nice little demonstration board. Some good ideas in here.