I recall burning three or four weeks of a sabbatical getting Saccade.com on the air with Wordpress. So much tweaking…

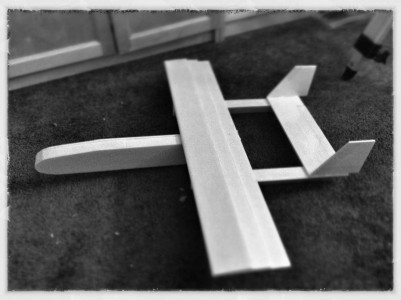

An “So” series foamflyer…

Today I spent a lot of time making bread and pumpkin cheesecake for tomorrow’s Thanksgiving day feast, but in between I decided to build some more parts for a “So” twin boom foam flyer, using the KFm3 wing that I photographed yesterday. My goal wasn’t so much to build a flying plane today, but to just test the design out, and see if there were any difficulties or tweaks to be made. So, I made two twin triangular booms, the 13″x4″ stabilizer, tail fins, and the body. Here’s the result:

It’s a fairly nice looking design. The twin booms and stabilizer presented no serious issues, except for maybe alignment: making sure they are parallel and at right angles to the wings and stabilizers. I cut the internal bevels on the boom freehand, which made them look a little rough, but that presented no real problem once they are glued and folded. The fuselage body was a bit trickier: the instructions call for cutting a 36″ long strip, 1″ wide that separates the two sides. I cut a pair of 1″ wide strips, since the stock that I had is maximum of 30″ wide. I free handed the curve at the front of the fuselage, cutting both sides simultaneously. I then glued the strip along once side with hot glue, then spread hot glue on the other side and lowered it down. It isn’t perfect, but seems okay. I haven’t covered it with packing tape: my skills at covering flat sheets are pretty good, but irregular shapes seem a bit trickier. I’m pondering building a similar plane, but using the Experimental Airlines 2.5″ square fuselage.

But it looks pretty good. I’ll be able to weigh the model and work out the wing loading and some of the balance issues. I’ll also be able to think about how to place the servos, receiver and battery. I may just hang it from the ceiling of my office.

Comment from Moe Naguib

Time 2/28/2013 at 3:30 pm

Looks like a good candidate for Video work, twin motors at the front of the booms would not have props showing up in the images. Two props with variable thrust tied to the rudder gives one the ability to do fairly flat turns as well, lots of positives for you design here.