I recall burning three or four weeks of a sabbatical getting Saccade.com on the air with Wordpress. So much tweaking…

Another stab at an Arduino bumper…

Earlier this week, I tried to print out the first version of my Arduino bumper. Sadly, our Replicator 2 had a malfunction mid print, and it’s still offline (a problem with the temp sensor) but that doesn’t mean I’ve been entirely stationary. I mentioned on twitter that I was having trouble using the minkowski operator to generate interior offset surfaces, and @kitwallace responded this pointer to some code he used which helped me generate a “lip” inside the outer wall that would snugly fit the Arduino. I also realized that this wall would bump into the backside of some of the pins, particularly around the DC jack, but also on the ICSP and header pins. So, I revised this a bit, and came up with this program:

[sourcecode lang=”cpp”]

module arduino_outline() {

polygon([[0, 0],

[0, 2100],

[2540, 2100],

[2600, 2040],

[2600, 1590],

[2700, 1490],

[2700, 200],

[2600, 100],

[2600, 0]]) ;

}

px = 2505.512 ;

py = 1198.031 ;

module icsp() {

translate([px, py-200, 31.25]) minkowski() {

cube([100, 200, 62.5]) ;

cylinder(r=50) ;

}

}

eps = 0.001 ;

s = 25.4/1000. ;

cl = 8 ;

th = 62.5 ;

module os() {

linear_extrude(height=250)

minkowski() {

arduino_outline() ;

circle(r=th+cl) ;

}

}

module is() {

translate([0, 0, -eps]) linear_extrude(height=250 + 2 * eps)

minkowski() {

arduino_outline() ;

circle(r=cl) ;

}

}

module final() {

difference() {

os() ;

is() ;

}

}

module neg() {

union() {

intersection() {

minkowski() {

difference() {

translate([-200, -200, eps]) cube([3000, 3000, 62.5]) ;

os() ;

}

cylinder(r=200+th+cl*2) ;

}

os() ;

}

final() ;

}

}

module holes() {

union() {

translate([550, 100]) cylinder(r=125/2., h=500, center=true) ;

translate([600, 2000]) cylinder(r=125/2., h=500, center=true) ;

translate([2600, 300]) cylinder(r=125/2., h=500, center=true) ;

translate([2600, 1400]) cylinder(r=125/2., h=500, center=true) ;

}

}

off = 31.25 ;

d = 31.25 ;

w = 31.25 ;

module relief() {

translate([1100, 100, 62.5]) translate([-w, -w, -d])

cube([1400+2*w, 2*w, 2*d]) ;

translate([740, 2000, 62.5]) translate([-w, -w, -d])

cube([1740+2*w, 2*w, 2*d]) ;

}

module slots() {

union() {

translate([-100, 125, 63+off]) cube([550, 350, 500]) ;

translate([-250, 1275, 63+off]) cube([625, 500, 500]) ;

translate([-cl, 125, 0]) cube([450+cl, 350, 500]) ;

}

}

$fn = 24 ;

scale([s, s, s]) difference() { neg() ; holes() ; slots(); relief() ; icsp() ; }

[/sourcecode]

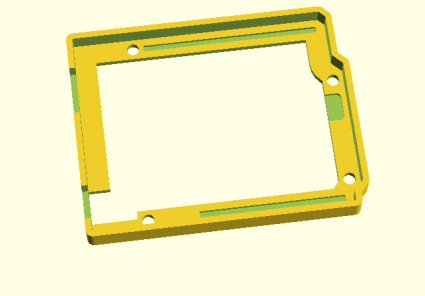

Here’s a quick picture:

It might be a few days before I can get this printed. If anyone uses this to generate STL and print it, I’d love to hear about what you think.

If not, stay tuned. I’ll get there eventually.

Comments

Comment from Mark

Time 3/21/2013 at 4:01 pm

Yeah, but this part in particular has modest structural requirements and consists of mostly empty space. 3D printing one costs about $0.05 per gram of material (I haven’t computed how many grams it is, but it isn’t a lot). If you were going to mass produce one, injection molding would probably be the way to go, but for prototypes, 3d printing is pretty reasonable. I should have one printed tomorrow, we’ll see how it goes.

Comment from Kevin

Time 3/20/2013 at 5:07 pm

I was just going to point out that your local machinist could probably run parts off like this with a mill in metal and not break the bank.