Merry Christmas to all, and best wishes for the New Year!

I’m in the middle of the “Winter Break” at Pixar. The studio mostly empties between Christmas and New Years, and they take the time to do some improvements and maintenance to the building. I thought it might be a good idea to continue my attempt to do similar improvements in my garage/workshop area, so that’s on the top of my list this week.

This endeavor generally reminds me of the Sherlock Holmes story The Musgrave Ritual, which opens with a lament from John Watson about his roommates rather untidy habits. I’m sure that were Carmen to read the following, she’d find some striking similarities to my own habits:

Our chambers were always full of chemicals and of criminal relics which had a way of wandering into unlikely positions, and of turning up in the butter-dish or in even less desirable places. But his papers were my great crux. He had a horror of destroying documents, especially those which were connected with his past cases, and yet it was only once in every year or two that he would muster energy to docket and arrange them; for, as I have mentioned somewhere in these incoherent memoirs, the outbursts of passionate energy when he performed the remarkable feats with which his name is associated were followed by reactions of lethargy during which he would lie about with his violin and his books, hardly moving save from the sofa to the table. Thus month after month his papers accumulated, until every corner of the room was stacked with bundles of manuscript which were on no account to be burned, and which could not be put away save by their owner.

The Musgrave Ritual

Carmen and I have been living in our current house for nearly twenty years, and our garage has increasingly become storage, and inefficiently used storage at that. All sorts of boxes and containers were strewn about, containing both treasure and crap in equal measure. But a few months ago, we had a problem with a leak in our water heater which created quite a mess and I’ve been trying to dedicate some time each week (mostly on the weekend) to separate the wheat from the chaff and turn the space back into a real, working space where I could tackle new projects in a more efficient manner. I call this effort “Project Virtue” in the hopes that I will develop tidier habits, and make bursts of creativity more productive.

Of course whenever you embark on a project like this, you end up with a bunch of sub-projects, and then sub-sub-projects. The hope is to prevent some kind of infinite regression like Atlas’ turtles (“it’s projects upon projects, all the way down.”) It feels that way, but I am making some headway.

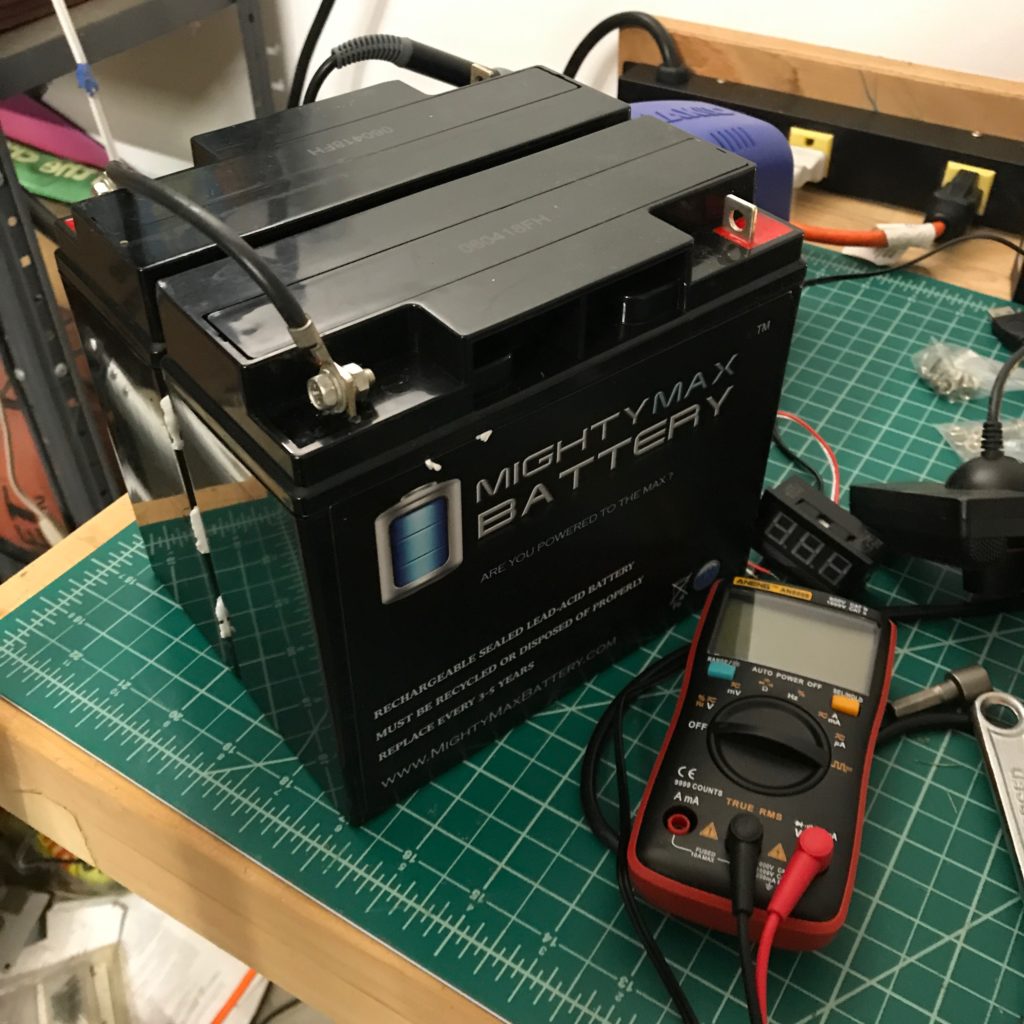

A couple of weeks ago, I mentioned that I wanted to repair my Black and Decker CMM1000 cordless electric lawnmower which seemed to have a completely dead battery that wouldn’t charge.

The batteries arrived over the weekend, and I got to work. The mower actually takes two batteries which were held together back-to-back with mounting tape. Luckily, I had some on hand, so I taped the new batteries together, and then transferred the shorting strap to place the batteries in series. A quick check with the multimeter indicated that the batteries were charged, and so I reinstalled the battery and tested out the lawnmower. Huzzah! Fired right up. I went ahead and used it to mow the front lawn. It has some pluses and minuses compared to my gas mower. It is much quieter, and the mechanism for adjusting the mow height is really nice and adjusts all the wheels simultaneously. But it is not as powerful, and I had problems using the bagging function (it’s better a simple mulching mower). I also have gotten used to my gas mower’s powered wheels, which makes it much easier to use despite both mowers weighing a similar amount.

After cutting the lawn, I also tested the charging adapter. There was a small chance that the adapter was also faulty, but it seemed to work okay. Note to myself: the charge meter only works when the safety is installed and you start the mower. It does not indicate the state of charge while charging. You should see the red led come on when charging, and it will turn green when charging is complete.

So, I popped the stack: mower is fixed. If it is going to take up space in the garage, it will at least be because it is a functioning tool.

Another sub-project was fixing the dog door in our garage. We’ve never owned a dog, but apparently one of the previous owners did. The door was fairly large-ish, and covered with a flap which had suffered over time. The net result was it was both drafty and allowed various varmints and critters (and on one occasion, a pregnant cat) to set up shop in our garage. So, I removed the hardware and found a scrap of plywood that I could cut to the right side and bolt in place over the opening.

I hit the board with a coating of Krylon exterior primer/paint, and screwed it in place. My perpetual problem of finding screws of the right size at our local Home Depot continued, but while cleaning I found my underutilized angle grinder, so the long bolts presented no real problem.

I also moved my aging Linux box to the garage, and got an inexpensive $80 LED TV from Best Buy, which I mounted using an unused TV mount from Harbor Freight.

I scrounged up a wireless keyboard and mouse, and I was good to go.

I’ve still got a lot of cleaning to do, but increasingly the floor is becoming visible, trash cans are filling and being hauled away each week (probably the current bottleneck) and I’m beginning to organize tools and work more efficiently.

But… I’m also in acquisition mode, and thanks to Santa, I’ve got some new additions. I’ve been wanting to have a chop saw for quite some time. I have borrowed one from the Richmond Tool library, but having one of my own seemed like it would be useful. I’m not much of a wood worker, but it would be great to be able to do small projects like building planter boxes and workbenches. Carmen must have been paying attention, because she ended up surprising me a Dewalt DW715 12″ compound miter saw. Very nice! Of course, I lack workbench space for it, so after reading some web reviews, I drove over to Harbor Freight and got one of their Heavy Duty Mobile Miter Stands using a 20% off Super Coupon. It is pretty beefy, and has a couple of features I really like. It has large wheels, and you can actually roll it around with the saw mounted on it. The mounting brackets are actually really nice, and have a two-stage release mechanism which makes it easy to take the saw off and put it back on. Things that could be improved are that there is a significant amount of play in the supports for the rollers, but some shimming would probably help considerably. The ability to store it upright against the wall is pretty nice for space-constrained workshop areas.

Ultimately though, I know I need some additional workbench space, and I want to make at least one on rollers. I don’t want anything too sophisticated, but I do want it to be sturdy and useful. I also didn’t want to fuss with it forever, I wanted it to be a project that I could complete for modest money, with a single trip to Home Depot and a Saturday.

That brings me to an expenditure where I’m trading time for money. I decided that it would be worthwhile to acquire a pocket hole jig, and settled for the Kreg K4 Jig. I could have gone cheaper, but I think that would perhaps be false economy. The larger system is designed to do work with 2×4’s more efficiently, and includes things like the specialty clamp and vacuum adapter for dust removal.

Kreg also maintains a list of cool projects, and I found this cool Easy Build Workbench that looks pretty much like what I envisioned: 32″ x 48″ with locking casters. The only modification I am going to make is to build it taller: I want my benchtop to be at 36″. I’ll probably get some 3″ locking wheels from Harbor Freight which should mean that the 2×6″ uprights need to be 32.5″ in height. I’m also thinking of adding a power strip to one end and a place to wind a power cord.

After I get this bench done, I have a couple of other projects in mind, including a stand for my drill press (it’s not bolted to the the current stand, which is probably not a good idea), a drill press table and fence, and maybe some additional jiggery to make the Kreg more useful. I’ll probably also do some planters for our back garden, and maybe some additional home improvements. And then I can get back to my electronics and ESP8266 hacking.

I’ve also got a friend coming over on Saturday to take away some of my telescope making inventory. It dawns on me that I have lots more stuff in my garage than I will use in my lifetime, and finding new homes for a lot of it will make other people happy and will also clear up additional space for me. If we discover anything cool while digging, I’ll be sure to post about it here.

Best wishes to all, and thanks for reading.