Practical uses for 3D printers…

I’ve been an on-and-off enthusiast for 3D printing for quite some time, but in the early days, it wasn’t what I would call “practical”. They used to be fairly unreliable. In particular, my aging Creality CR-10 had difficulties with bed leveling, and while I kept modifying it to add sensors like the BL-Touch to automate that process, at some point I simply got fed up with it and let it sit. But technology kept increasing, and there are some new consumer level printers made by companies like Bambu Labs which are faster and employ lidar and other fancy bits of tech to print faster than ever before.

As yet, I don’t have one of those. But rather than continue to tweak my CR10, I decided last year to buy a Elegoo Neptune Pro 3, which I got on a Black Friday sale for around $250. And it was much better than my Creality CR10. It’s bed leveling just works, and I’ve done dozens of prints with the only real failures being stupidities of my own. And the quality is quite good.

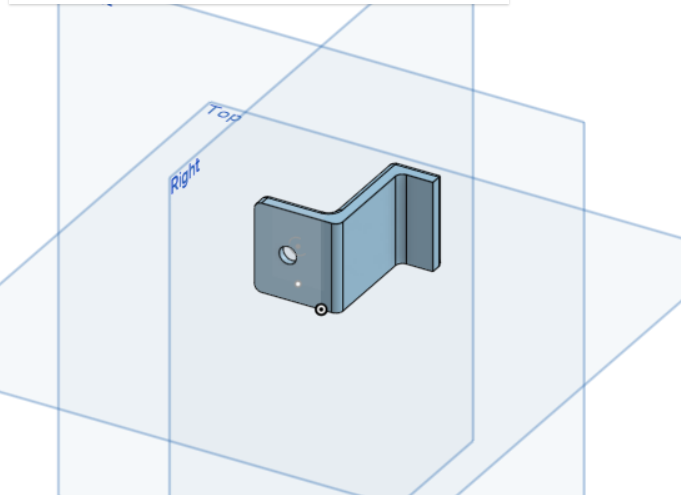

And, it’s reliable enough that I can design and print parts without taking an entire day. For instance this week I had an issue where I wanted to fix a window that the previous owner had literally screwed shut (presumably as a security measure). I needed to open that window today for maintenance, but he had driven these self tapping screws in very close to the edge, and I couldn’t get a wrench or even a nut driver in very easily to take them out. I didn’t want to replace them in the same way, so instead I designed and printed these little clips using OnShape, a free and web based parametric design software that I recommend to anyone. It may not be quite as capable as Fusion360, but the ability to design parts using any web browser (I use Chrome on both Windows and Linux machines) and have models always available is pretty handy.

Anyway, I designed this part with chamfers and better clearances after taking a few measurements, and printed them in some ASA filament I had lying around, which should be more UV resistant than others. These look tidier and were less annoying than just screwing through the window frame. And should I ever need to back them out, there is enough clearance to just use a nut driver to back them out. I printed four of them in just 25 minutes, taking almost no filament. Problem solved.

Another thing I like to use 3D printing for is to make things like lens caps. I have this old pair of German WWII aircraft spotting binoculars.

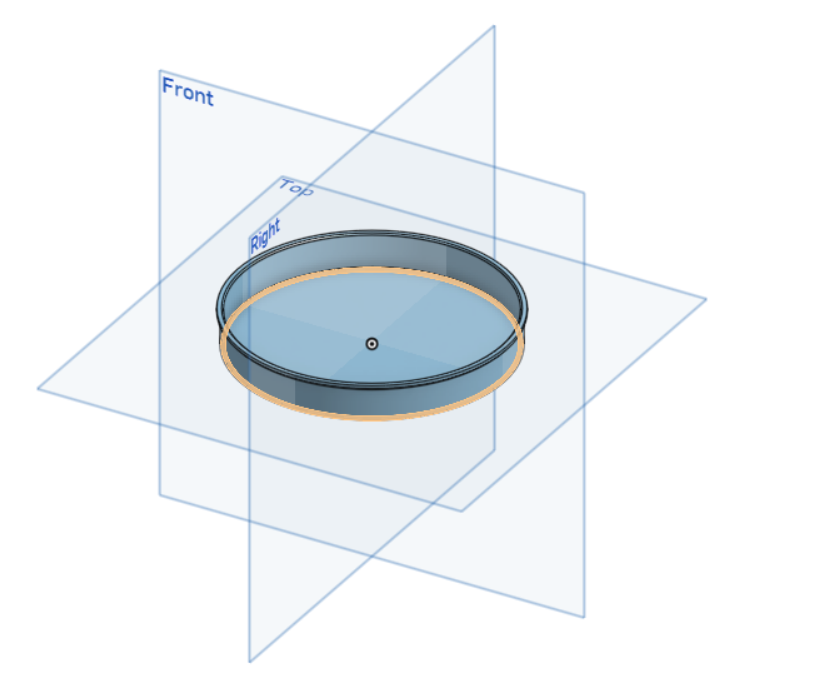

They are beasts, but very comfortable to use for astronomy, with large eye relief, adjustable inter-ocular distanc, and a sturdy tripod. I often use them to view lunar eclipses and the like. But what they lack is dust caps. So, the other day I dusted off my OnShape skills and took some measurements, and quickly generated this lens cap model:

I had some white TPU filament, which is quite flexible and which I have used to make a dustcap previously for my 6″ f/4 Newtonian that I made decades ago. The model is a very simple capped cylinder, with a chamfered rim around the edge to add some thickness for enhanced sturdiness. The chamfer also makes them slide on very easily, even though the fit is fairly tight. That means that they don’t fall off very easily either. The TPU is flexible, and even though the thickness is only 1mm, they are incredibly sturdy: I think I would actually have to work fairly hard to tear them apart. I should note that TPU was hard to print on my old CR10, but I’ve had literally no failed prints using TPU, despite it being a very soft and flexible filament.

I mentioned this model to a friend of mine who said that he had long ago lost the caps for his pair of Nikon binoculars. I told him to send me the dimensions and I’d print him some. He lives up on Oregon, so I mailed them up to him, and he mailed me back this photo:

They apparently work perfectly. I didn’t have TPU in black, which would have looked nicer, but hey, they work and will be good at protecting his optics.

3D printing can be really valuable in creating custom items, even if (or maybe especially if) they are low value objects. Think about it this way: how much would you pay to get a new set of lens caps for a set of binoculars? Even $5 seems excessive, but you might do it if you knew they would fit your very special binoculars. But such a thing may not even exist/be available if your particular set is old or rare. Being able to create a version which actually fits for just pennies seems really cool to me.

None of this is very exciting, but I do feel oddly happy having done this.

I still need to take some measurements to do caps for the German binocular’s eyepieces, which have a tapered shape which is a bit more complex. I’ll probably get to that today.

Hope you all are having a good weekend.

I recall burning three or four weeks of a sabbatical getting Saccade.com on the air with Wordpress. So much tweaking…