On the allure of Quora and plans for a new brainwagon future.

For several years, this blog was my major creative outlet on the Internet. Facebook was founded in February of 2004. Twitter was founded in March of 2006. But I was already using WordPress to scribble down random bits of flotsam and jetsam as early as July 21, 2002. Over the next fifteen years, I’d write 4,211 posts about random stuff of interest. At my peak I’d get maybe 300 views of my stuff per week. The topics were wide ranging and eclectic, which basically matched the way my brain works. I concentrated mostly on geeky stuff. For a while there was a lot about podcasting (and I recorded 100 episodes of my own “brainwagon radio” mostly while commuting). I posted a lot about amateur radio. I wrote little bits of code. I tinkered with Arduinos. I talked about cryptography and computer graphics. I scribbled notes to myself about things that I thought I’d need to remember, like how to use ssh to do tunnels through my firewall. I read and passed on notes about people who built their own CPUs. I took photographs. Occassionally, I’d write a little about politics, or announce the release of a movie that I had worked on.

You never knew what you were going to get.

Some 300 or so people a month visited my blog. Those were the real viewers: WordPress was pretty good at getting rid of the 760,000 (and counting) attempts to inject content spam onto my blog.

But in 2015 I suffered an injury to my neck that laid me up for a few weeks with terrible back pain and arm weakness. It recurred in 2016, even worse. I ended up having to have two different injections in my C6/C7 vertebrae, and was in constant pain through my left arm, which became really weak. I was out of work for 60 days. As I sat around recovering, I discovered Quora.

Quora is a question and answer website. Anyone can create an account and ask and answer questions on a wide variety of topics. I was stuck at home. Injured, bored, and unable to do very much without making myself ache, I started to read and answer questions. At first, it was mostly about stuff I knew about: computer graphics, astronomy, and telescopes. But since I was sitting at home, I was also watching a lot of political news of the day, so I started answering questions about that as well. The run up to the election in 2016 gave me lots to think about, and I had lots of time.

I didn’t think too much of it at first. Then I had my first answer that received one thousand views. Pretty soon, I had answers which received one thousand upvotes. People started to follow me. I reached one hundred followers. Then one thousand. Then five thousand. As of today I’ve got about 7,200 followers, and over nineteen million views, and written around one million words spread out over 6,785 answers.

It was obvious to me that Quora was a much more powerful platform than my blog ever was. I received Top Writer status for both 2016 and 2017, and they sent me a nice laptop bag to proclaim my status.

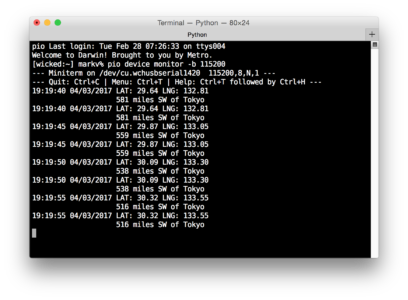

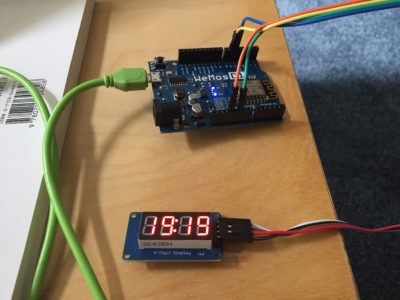

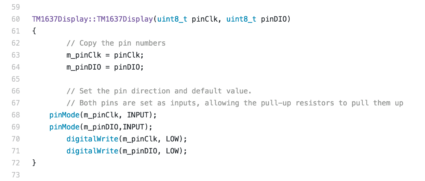

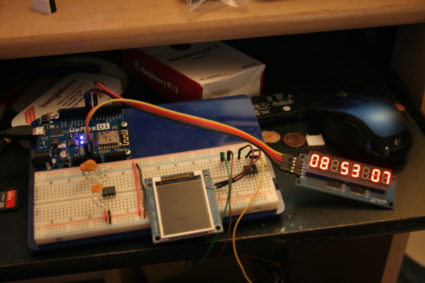

I have to say that this appealed to my ego, and as a result, it began to dig into my time that I normally would have spent on my blog, which slowed to a trickle over the last six months. It’s not that I haven’t done anything interesting and Quora is taking 100% of my time. I upgraded my soldering equipment to include a hot air rework station and a better soldering iron. I started to import lots of cool modules and stuff from China and play with them. I ordered a kit for a 3D printer and built it.

But I had stopped writing about the things that I do, and instead spent that time answering questions about stuff which mattered less to me, but which were (apparently) interesting to more people.

Over the holiday break, I began to consider where this state of affairs had led me.

Yes, it’s flattering to get comments and followers. It’s easy to add your voice in the form of opinion or indignation, and in a political environment where you feel like you need an outlet, it can be quite attractive to use easy outlets like Facebook, Twitter or Quora to vent.

But it’s not really what I want to be doing. Or at the very least, the amount of effort that I am placing in that area is out of proportion to its importance.

My blog was about stuff that I liked and stuff I was doing. It was intended to be half documentation and half inspiration. The documentation was often for me: to remind me of the stuff I had learned and might need again. The inspiration was to get others to look into the same sort of things that I like, and to come talk to me about them.

Quora doesn’t serve either of those purposes, but it is taking all of my time. So, I’m trying something new in 2018.

I’m trying to dedicate just thirty minutes of my day to do something and write about it on my blog. It doesn’t matter what it is. It might be a recommendation for a book I enjoyed. It might be projects I’m working on. It might be a review of some tech product that I found especially useful. It actually doesn’t matter what it is. It will begin with something I’m doing or thinking about, and something which I think might be worth sharing. If any of my old readers (or any new ones) find anything interesting, I’ll hope that you’ll follow my blog and comment. I’ll probably work on ways to make sure that it is as easy as possible to do so, and I might even start thinking about using a platform like YouTube to do interesting and engaging stuff. But my goal is to get back to discussing the stuff that I find fun and interesting.

I hope that you will find it so too, and come back again soon.

I recall burning three or four weeks of a sabbatical getting Saccade.com on the air with Wordpress. So much tweaking…