A day at the Official Propeller Conference

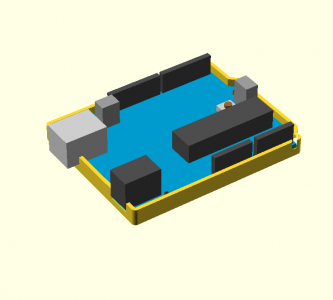

Even casual readers of this blog know that I’ve enjoyed playing around with the Arduino and the Atmel AVR chips. I really like them, and have used them for a variety of personal projects, as well as using them for a variety of educational projects for a local high school where I mentor students. But I also have a variety of other boards, from MSP430s to the BeagleBone, from the Raspberry Pi to the Parallax Propeller.

The truth is, I haven’t done a lot with the Propeller board. I must admit that a lot of it is simply inertia: if something you already know fairly well serves your needs, then learning something new is often a distraction from your task at hand. But there are things about the Propeller that I do find interesting and compelling.

It’s fast. The chip can be clocked up to 80Mhz, and has 8 cogs, each a 32 bit core with 2KB of local storage for instructions and data.

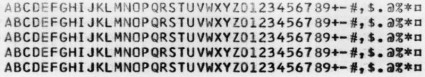

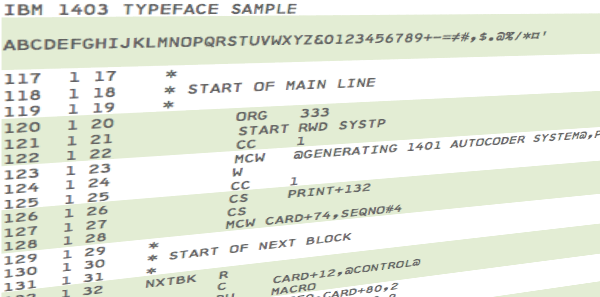

It has a built in byte code interpreter for SPIN, a high level language. Each cog can execute about 80,000 of these high level byte codes per second, or about 640,000 max if all cogs are funning. I have mixed feelings about Spin, but it’s a cool idea nonetheless.

It avoids interrupts, preferring to use cogs to process events. Interrupt processing is challenging for new programmers (and in some cases, even experienced ones) and the cog model might be easier and more flexible for many real time tasks.

It avoids dedicated hardware peripherals, instead providing “virtual” peripherals as software. Because the chip is fast, and there are many cogs, it’s possible to implement many devices such as UARTS, PWM, servo drivers and even video as code which runs on a particular cog in parallel with the user program. This gives the programmer a great deal of flexibility. SPIN supports a library of user-contributed objects which can really lend to the flexibility of the Propeller.

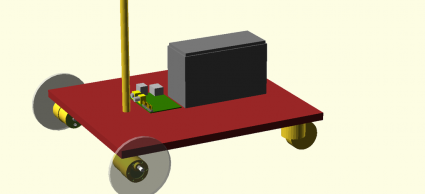

So, there is lots to like! So, for the second year in a row, I’ve shuffled off to meet some of my friends from tymkrs.com at the Official Propeller Conference. It’s a fairly small get together of Propeller enthusiasts, hosted by Parallax and featuring short presentations on Propeller hardware and software techniques. I had a lot of fun. Parallax is a remarkably small company, run by Ken and Chip Gracey, and having maybe forty employees. Besides the Propeller, they manufacture a bunch of other items, including sensors and robotics items. The highlight of the day was a talk by Chip about the upcoming Propeller 2. Chip’s talk was remarkably informative, and so devoid of normal marketing bull that I actually blinked several times at his honesty.

Propeller 2 looks very cool. To me, the most exciting thing is that it one ups the flexibility of the Prop 1 in allowing any pin to be configured as digital or analog, and an input or output. The Prop 1 has been used by hams to directly generate beacon signals but the new capabilities would seem to open a variety of demodulation as well as modulation techniques. Chip said that the first actual silicon for the Prop 2 will be arriving at Parallax this Monday, and that he’ll let us know via the Parallax forums how that goes. I’ll be paying attention.

I had a great time, culminating with a BBQ dinner with Atdiy, Whisker, Roy, Joe, and some of the Parallax crew. It’s inspired me to actually dig in and start learning Spin. I’m staring over at my Parallax board, happily blinking LEDS. It’s a start.

More details on the Propeller as I goof around.

I recall burning three or four weeks of a sabbatical getting Saccade.com on the air with Wordpress. So much tweaking…