Post Field Day Report on K6HX Beacon Operations…

So, part of my incentive on working on my WSPR beacon was one of my coworkers decided to try to do some operating from the local Emeryville Marina, and I thought it might be nice to use the opportunity to try to pack up my WSPR setup and see if I could get some spots using solar/battery power.

I wrote up some of the early experimentation to get the beacon working, but as of then I hadn’t actually gotten on the air. To do that, I needed two things: an antenna and (to be a good RF citizen) a low pass filter to make sure that I wasn’t scattering horrible harmonics everywhere. While it was true that I was outputting a scant 10mw, I thought that being a good citizen was important.

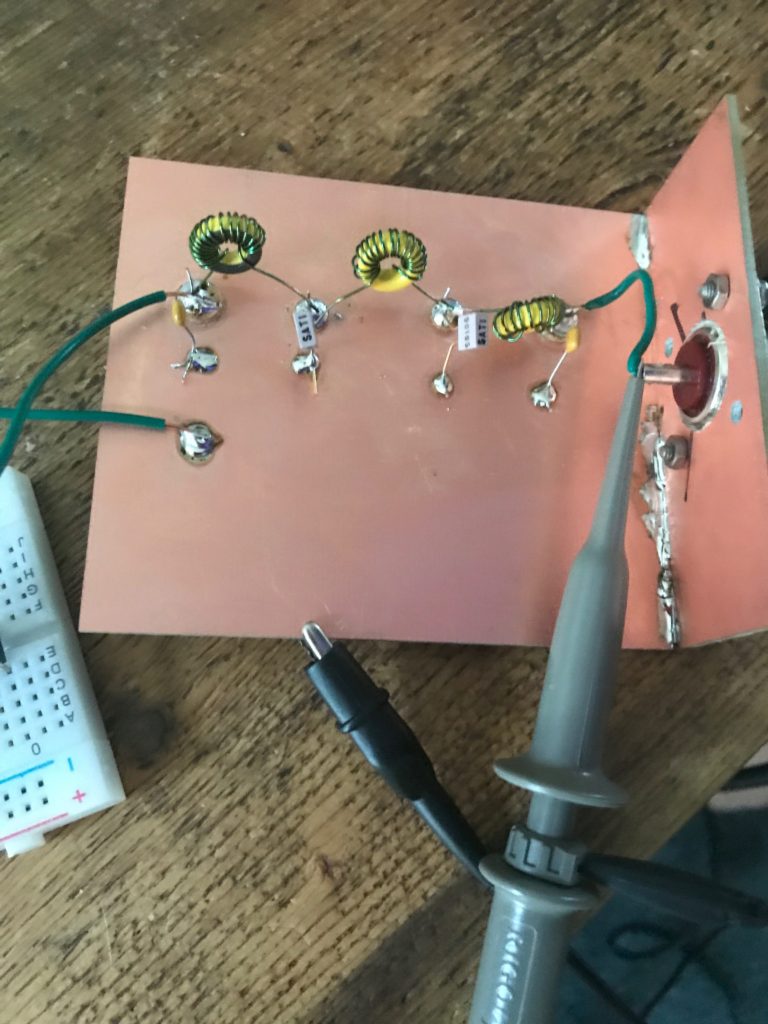

I had some yellow T37-6 cores lying around from a previous bout of homebrew exploration, and dug out an article on constructing harmonic filters by the awesome (but sadly SK) George Dobs, G3RJV. I dug out some copper clad and wired up the filter using some islands that I punched out of scrap copper clad board. I am a total novice at this, so the board layout is terrible and stupid, and the leads are too long: in short, everything I did should be viewed with skepticism.

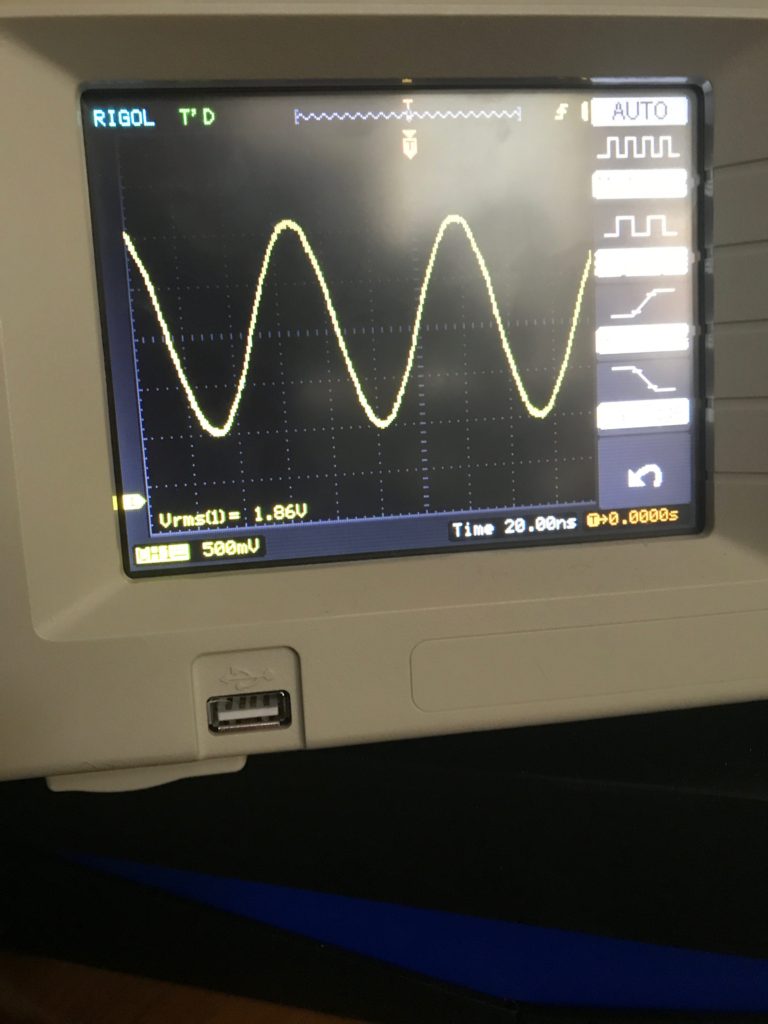

But as crappy as it is, it seemed to work. I snapped a quick picture of the output as it goes to my antenna, and the previously ugly triangle-ish wave now resembles a reasonable sine wave.

I must admit that I was somewhat befuddled by the Vrms as measured by my scope. The equation for output power suggests that power equals Vrms squared divided by the resistance. If we assume my antenna was a nominal 50 ohms (it’s not, but let’s pretend) then this would indicate an output power of nearly 70mw, which doesn’t really make sense. My antenna had only been “tuned” in the grossest sense, and probably had an SWR of around 2.5:1, which suggests that it’s characteristic impedance was probably a lot higher. For the purposes of WSPR, I configured my output power as 20mw, which I thought was probably still generous, but in the right ballpark. I made a note to myself to figure this out later.

I still needed an antenna. While cleaning my garage, I found a pair of 20m whip antennas and an MFJ 347 mini dipole mount. I mounted these on a small piece of conduit, and then built a quick stand to hold it up, consisting of a 5 gallon bucket, a small round of particle board that I had left over from another project, and four pieces of two by fours to act as feet. Here it is, setup on my back patio. Yes, I know that the antenna is mounted too low to be good or efficient. This entire project was designed to be a hack, and for maximum ease, not permanence.

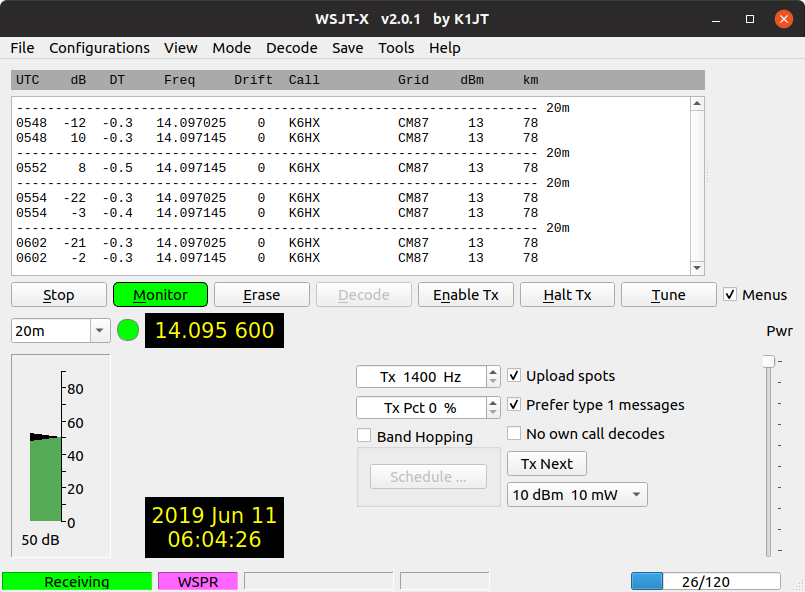

I set it up and home and set it beaconing. I didn’t get the torrent of spots that I had gotten when I had used a similar setup with 5w of power (using my FT-817) but a few minutes later I did get a spot from KA7OEI from DN31, a distance of about 933 km.

Huzzah! Thought I. I was ready for field day. Mind you, the entire thing was still just a pile of breadboards constructed out of wire. I decided to use my Chinese charge controller and a 20w panel to drive it and to recharge a 7aH lead acid battery. I packed it all up and headed to Emeryville on Field Day.

I’d like to report success, but the fact is that once I got it set up, it was apparent to me (by a lack of blinking lights and LEDs) that it wasn’t working. I wasn’t sure what was wrong, but I had failed to bring my laptop so debugging it in the field seemed like it wasn’t going to happen. After a couple of hours, I decided to pack it in. Sad.

The next day I unloaded it from the car and tested it out. The Arduino and the LCD unit seemed completely dead. I reflashed the code onto a new Arduino Nano, moved it all to a single breadboard, and reset it up in the backyard, and it has been beaconing on 20m, entirely powered by solar since then.

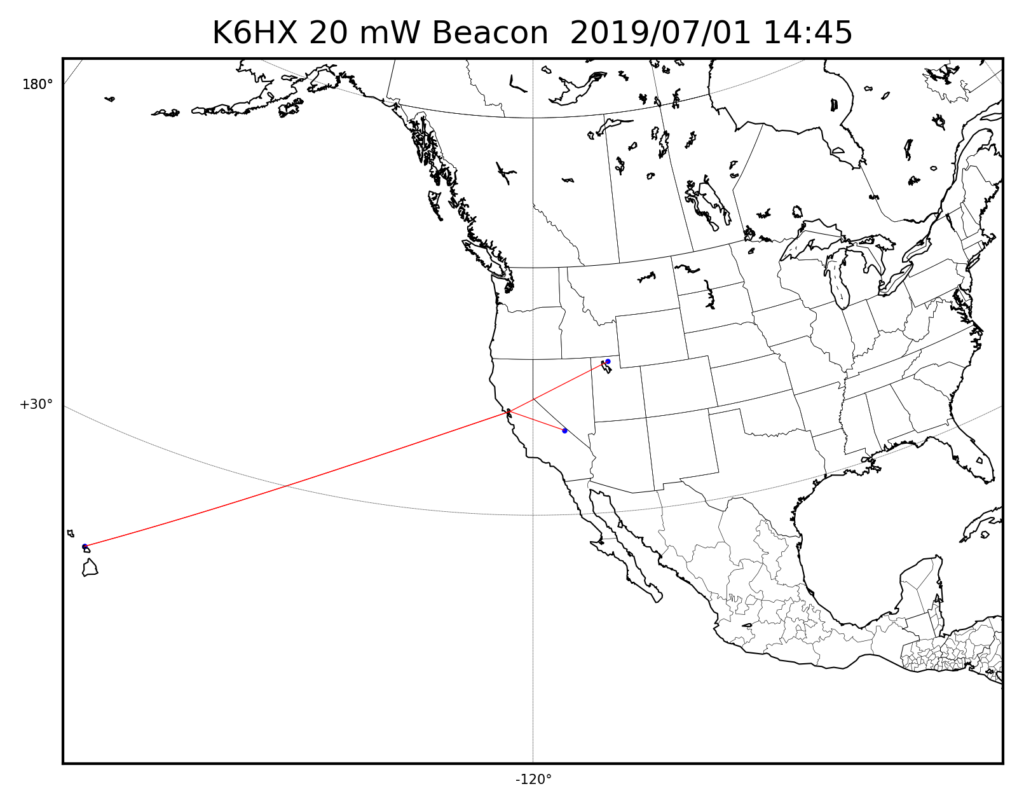

Since then, it has been spotted by 15 unique stations. By far and away the most reliable connection has been to KA7OEI-1, who has heard it 337 times in the last week. ND7M comes in next, with 118 spots. Distance records are pretty much evenly split between AI6VN/KH6 in Hawaii, and WD4ELG in North Carolina.

I made a small map which updates frequently, showing all the spots for the previous 24 hours. You can view that from my home webserver, at least until I get bored with it and take it down. I used the Python matplotlib to generate the maps, this one being an example.

I’ll probably try to get this up more or less permanently, and may add a small RF amplifier to boost its output to around 100mw. I will probably also shift to using an ESP8266 based module so that I can monitor and control the system via WiFi. I’ll update you when I get that going.

Hope you enjoyed.

I recall burning three or four weeks of a sabbatical getting Saccade.com on the air with Wordpress. So much tweaking…